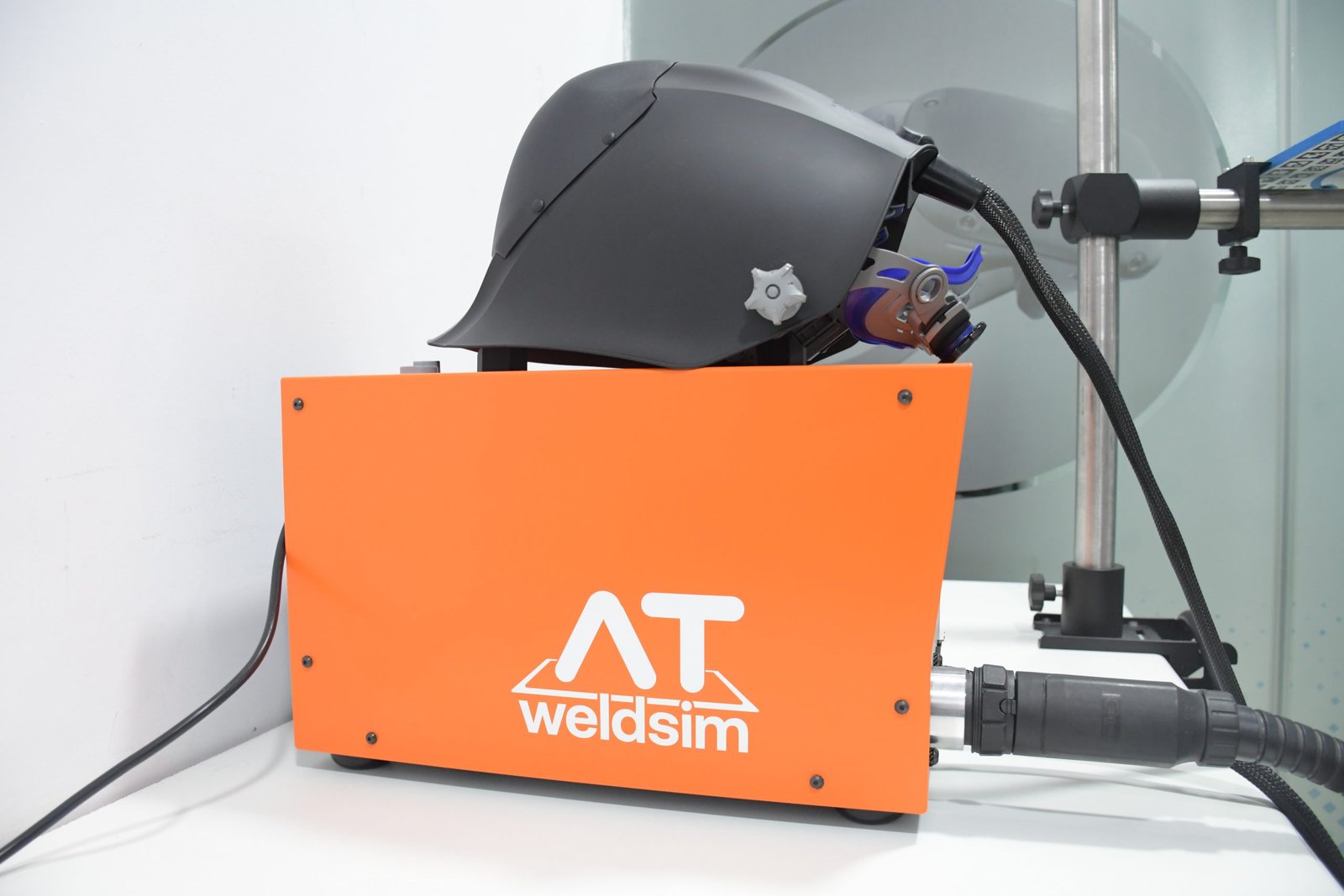

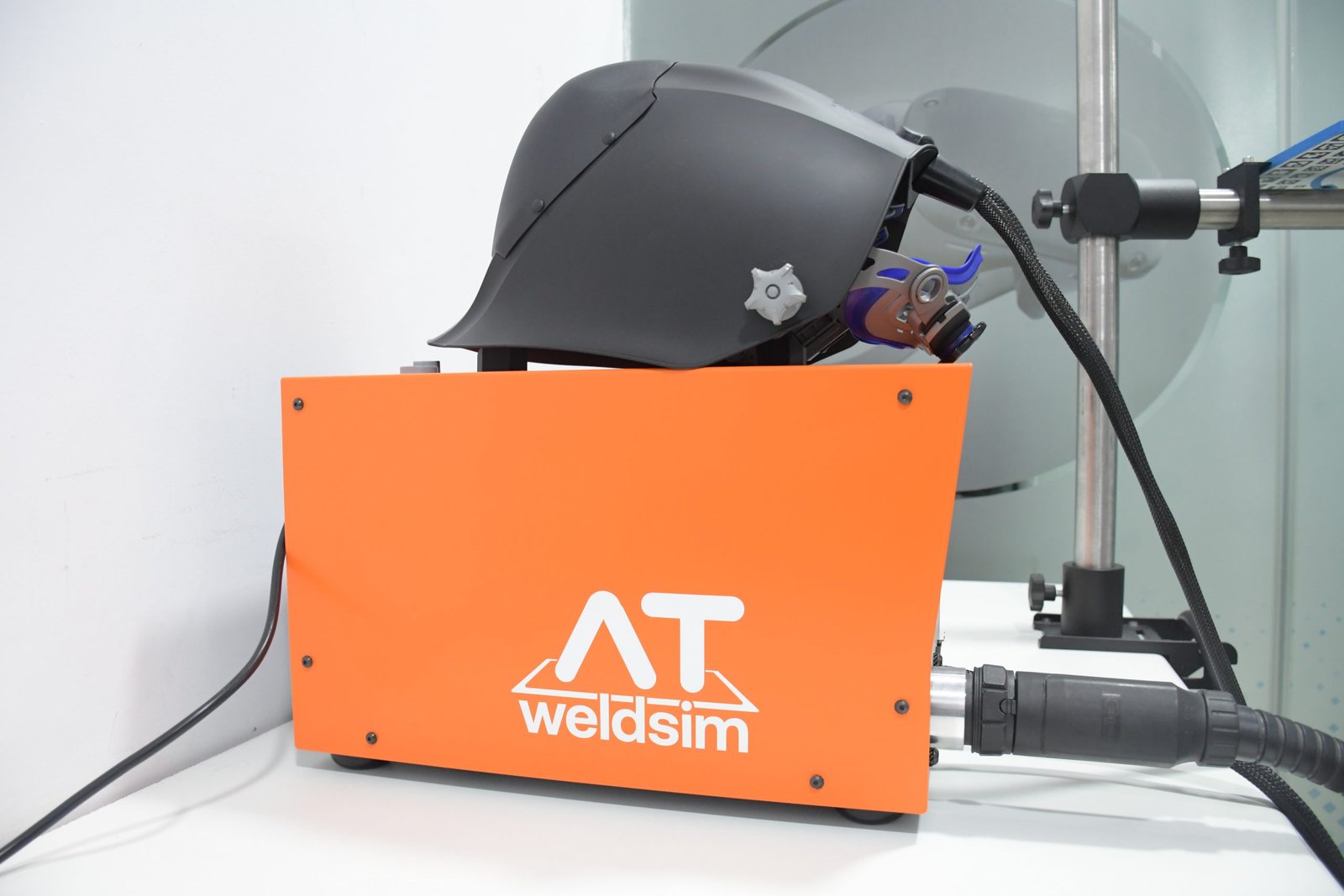

ATWeldSim - Augmented Training Welding Simulator

AT WeldSim is an enterprise-grade welding simulator designed to accelerate skills development, reduce operational risk, and significantly cut down training costs. Built using augmented reality and real welding equipment, AT WeldSim offers immersive training environments without the hazards of traditional methods. It empowers organizations to produce highly skilled, certification-ready welders with measurable precision, all while maintaining workplace safety and cost control.

Why Choose ATWeldSim?

Welding is one of the most in-demand industrial skills, yet training welders can be expensive, risky, and resource-intensive. ATWeldSim solves these challenges by:

-

Reducing material and energy costs with virtual practice.

-

Allowing repetitive, risk-free training sessions.

-

Delivering realistic feedback to improve skill retention.

-

Supporting both beginners and advanced welders with adaptive modules.

With ATWeldSim, training centers, industries, and educational institutions can standardize skill development and ensure consistent results.

1.Real Equipment with AR Integration

-

Trainees use actual torches, helmets, and positions, enhanced by high-fidelity AR overlays - ensuring skill transfer to real-world scenarios.

2. Multi-Process Simulation

-

Supports MIG, TIG, Stick, and FCAW with adjustable parameters for joint types, materials, positions, and defects.

3. Risk-Free Learning Environment

-

Eliminates fire hazards, toxic fumes, and burn injuries—compliant with safety-first protocols in all environments.

4. Real Equipment Integration

-

Use actual welding tools, torches, and helmets with AR markers.

-

Hands-on experience without consuming materials or gases.

5. Automated Performance Analytics

-

Real-time feedback on angle, arc length, speed, and consistency - empowering trainers with actionable insights.

Accelerate Certification Readiness

AT WeldSim prepares welders for certification in record time by delivering targeted, measurable training experiences - with simulation data that reinforces learning.

Reduce Material & Operational Overhead

Supports MIG, TIG, Stick, and FCAW with adjustable parameters for joint types, materials, positions, and defects.

Risk-Free Learning Environment

Eliminates fire hazards, toxic fumes, and burn injuries - compliant with safety-first protocols in all environments.

Automated Performance Analytics

Real-time feedback on angle, arc length, speed, and consistency - empowering trainers with actionable insights.